Unlike spark Ignition combustion chambers, the main important function of the combustion chamber of CI engines is to allow the injected fuel to properly mix with the pre-compressed air in a short time. In this article, we are going to discuss the different types of combustion chambers for CI Engines.

In Compression Ignition engines, Turbulence is necessary to mix the fuel within a short period after injecting the fuel into the combustion chamber. It can be controlled by the combustion chamber shape and design. Compression-Ignition engine combustion chambers are classified into two categories.

There are two different types of combustion chambers for CI Engines.

Direct Injection type combustion chambers are also known as the open type combustion chambers. This open type combustion chambers, the combustion chamber volume will be located in the cylinder. The fuel will be injected directly into the combustion chamber with the help of the fuel injector.

There are four design variants available in Direct Injection type combustion chambers. those are

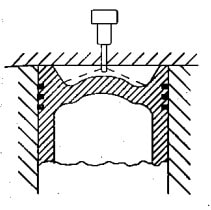

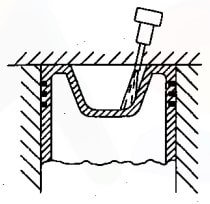

Shallow depth combustion chambers are mostly used in the heavy engines running with the low speeds. As you can see the shallow depth chamber diagram, the depth of the cavity provided in the piston is quite small and the diameter is large. Due to the large diameter, there will be almost negligible squish.

As you can see the hemispherical chamber, the depth to the diameter ratio can be varied. so that the squish can be controlled to attain better performance.

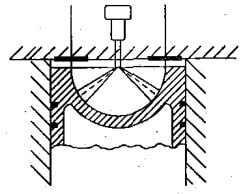

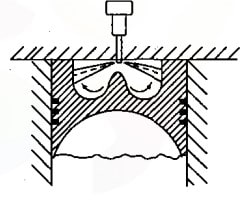

In a few modern diesel engines, this type of combustion chambers was implemented. As you can see the Cylindrical Chamber diagram, the shape of the combustion chamber is truncated cone with the base angle of 30°. The Squish can be varied by varying the depth. The swirl can be produced by masking the valve for nearly 180°of the circumference. Squash also can be controlled by varying the depth.

This Toroidal chamber design is mainly focused to provide the powerful Squish along with the air moment. As the more Squish, the mask needed on the inlet valve is small and there is better utilization of oxygen.

In this type of combustion chambers, they are having two parts. One part will be located in the cylinder and the other part will be in the cylinder head. The fuel will be injected into the part which is located in the cylinder head.

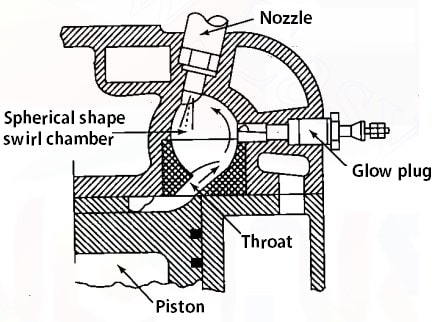

This is also known as the Ricardo swirl chamber. Swirl combustion chamber consists of the spherical-shaped chamber located in the cylinder head separated from the engine cylinder. During the compression stroke, 50% of the air will be transferred to this swirl chamber. In this spherical shaped swirl chamber, the fuel will be injected with the help of a nozzle and the combustion will be initiated.

The main drawback of this chamber is that the heat loss is greater compared to the open combustion chambers.

These chambers are used where the less quality of fuels are used. Where reliability is the main objective than the fuel economy.

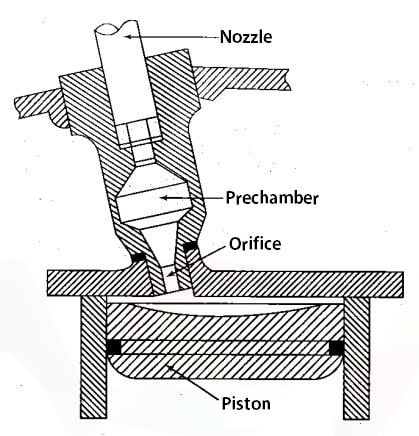

As you can see the above diagram of the Precombustion chamber. It consists of the Prechamber connected to the main chamber. This Prechamber located in the cylinder head. This Prechamber volume accounts for 40% of the total combustion space.

During the compression stroke, the air will be injected into the Prechamber the combustion will be initiated in it. But the bulk combustion will be taken place in the main chamber only. About 80% of the energy will be released in the main combustion chamber.

The rate of pressure rise and the maximum pressure attain during the combustion process is comparatively low than the open combustion chambers.

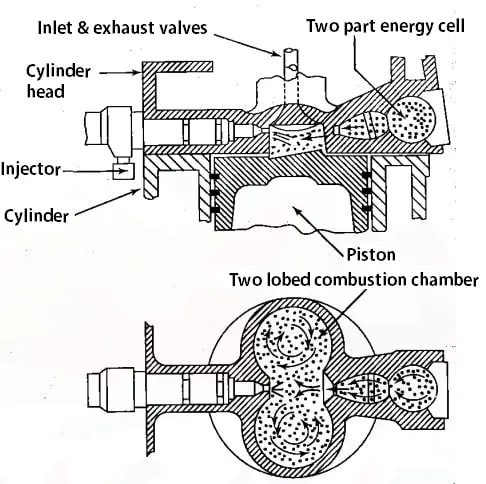

In this combustion chamber, the clearance volume will be shared by the two parts. One portion of the clearance will be in the main cylinder. The second portion will be called the energy cell. In energy cell itself, there will be two parts again. One is major and the other one is minor which were separated by the main chamber connected by the narrow orifices.

The nozzle injects the fuel across the main combustion chamber space towards the open neck the air cell.

During the compression stroke, the main chamber pressure will be more than the energy cell pressure. When the temperature reaches high in the main chamber, The combustion will starts in the main chamber initially. In the energy, the cell contains the well-mixed charge, due to the heat release in the main chamber the high-pressure combustion particles will blow out thru the small passages into the main chamber. This high-velocity jet produces swirling motion in the main chamber thereby thoroughly mixes the fuel with the air, therefore the combustion will be completed.

These are the different types of combustion chambers for the CI engines.

We have discussed the different types of combustion chambers for the CI engines. Those are the direct injection type and the indirect injection type. They are further design variants available. We have discussed them also with neat pictures. If you have any further thoughts on this topic, let us know in the comment section below.

Mechanical Engineer, Expertise in Engineering design, CAD/CAM, and Design Automation. More

Jonathan Dahlin says

Does the air cell chamber produce less pollution than a direct-injected Diesel engine?

I think precombustion chamber and Ricardo swirl chamber engines have less mpg than direct-injected Diesel engines, but produce less pollution for a given amount of fuel consumed than direct-injected ones. I could be wrong, but that’s what I would think.

Byantuyo Daniel says

Sketches showing direct and indirect injection chambers

Bhagwan Acharya says

What are the fault findings on combustion chamber?